The origin of base bending

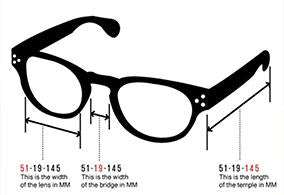

The lens consists of two curved surfaces before and after the lens. According to this structure, the composition of the lens shape can be numerous. When choosing the most beautiful crescent shape to fit the face, there are many combinations. This is very inconvenient for the mass production of lenses and product control in factories, especially for mold configuration, quality control, and finished product classification, etc., which will be messy, cumbersome, and irregular, and bring inconvenience to the store's stock preparation, preparation and customer service. Therefore, designers determine a reference surface for the lens and then based on this, according to the diopter, calculate the other side of the matching surface. This reference surface is called base bending.

The application of base bending

For the lenses produced by domestic glasses factory mass production, the base bending is based on the shape of the lens, diameter, refractive light level. The positive lens base curve is fixed on a concave surface. Negative lens base bending is fixed in the convex surface, and the other side is the luminosity matching surface. Common specifications are -2.00DS, ±3.00DS, ±3.50DS, +4.00DS, +5.00DS, +6.00DS, etc. Usually, the factory will determine the applicable base bending of each luminosity according to the light level in the internal control standard of the enterprise. The principle is that the larger the diameter of the lens or the higher the diopter, the flatter the base bending (shallow). Special high-bending lenses that require customization are not included.

What kind of base bending is good?

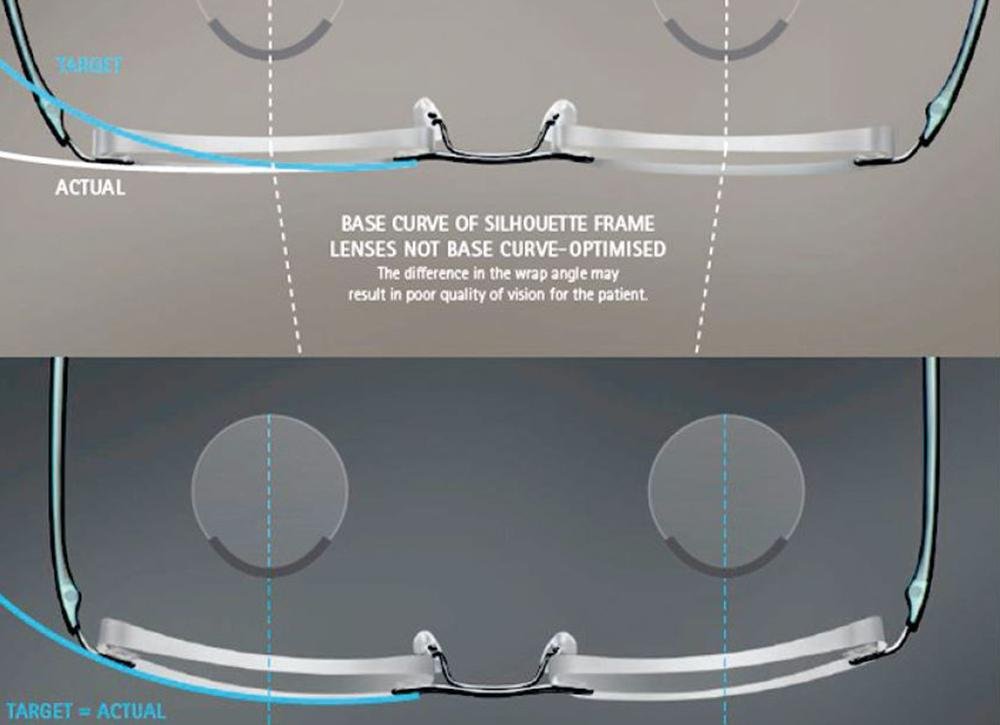

Base bending is an artificial lens structure foundation for the mass production of glasses, in order to reduce mold configuration and reduce the number of finished products classified and stored for easy control. The lens blank diameter diopter, do not touch the eyelashes when wearing a beautiful appearance to minimize aberration and other factors are considered. Designers take these factors into consideration before determining the appropriate specifications. This is a non-standard specification unless it is specifically required.

For example, what happens when a pair of frames with a large curvature matches a nearsighted lens with a small base curvature? If the lens with a smaller base curve (relatively flat) is directly used for trimming assembly, the lens will change the arc of the frame, affecting the wearing. The horizontal distance from the optical center of the lens will be different from the original setting. By changing the direction of the tip of the lens to fit the frame, but can cause the rim of the lens to "bulge", which is not beautiful but also changes the "actual luminosity" of the lens. At this point, you need to customize the curvature of the larger lens.