What is a drop ball test?

The Drop Ball Test, known as the Basic Impact Test, is an Impact Test administered by the Food and Drug Administration to determine the safety of eyeglasses. Eyeglasses (sunglasses, exercise glasses, near-sightedness glasses, reading glasses, etc.) are a category of medical devices covered by the Food and Drug Administration. When glasses are exported to the United States or put on shelves on Amazon,eBay, and other platforms, they need to be registered by FDA. Besides the product listing, when the product passes the customs, the company may be asked to produce a Certification Statement of Impact Resistance stating that the product meets 21CFR801.410 Drop Ball Test requirements.

Operation and Requirements of Drop Ball Test

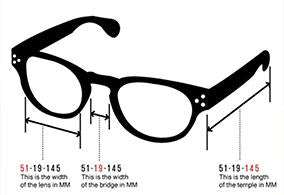

The ball, which is 0.625 inches in diameter and weighs 0.56 ounces (16 grams), falls from 50 inches (127 centimeters) and hits the center of the lens. The geometrical center of the lens should be struck by the ball within a circle 5/8 inches in diameter. If the lens does not break, it is called a "safety lens." There can't be anything that restricts the ball from falling. It cracks across the entire thickness, containing laminated layers (if any), and divides into two or more separate sections across the entire diameter.

What does the Drop Ball Test have to do with the eyewear industry?

FDA mandates that eyewear products must ensure their safety. Impact resistance is a basic norm for binding glasses and/or lenses in the United States. The FDA does say that a drop ball test must be performed on every glass lens for prescription use. The FDA-regulated eyewear products are common in the everyday lives of the public, and the FDA considers impact-resistant lenses to be an important part of the safe design of these devices. Today, "safety lenses" are rarely mentioned in our sales, but in the 1990s, when resin lenses first entered the Chinese market and glass lenses still dominated the market, safety lenses were a pretty important concept. At the time, the hardening technology has not been upgraded, and the resin lens is easy to wear out than the glass lens. The eyewear industry is relying on lightness, safety (anti-impact), comfort (anti-ultraviolet) step by step to achieve the market share of resin lenses from 1% to 100%.