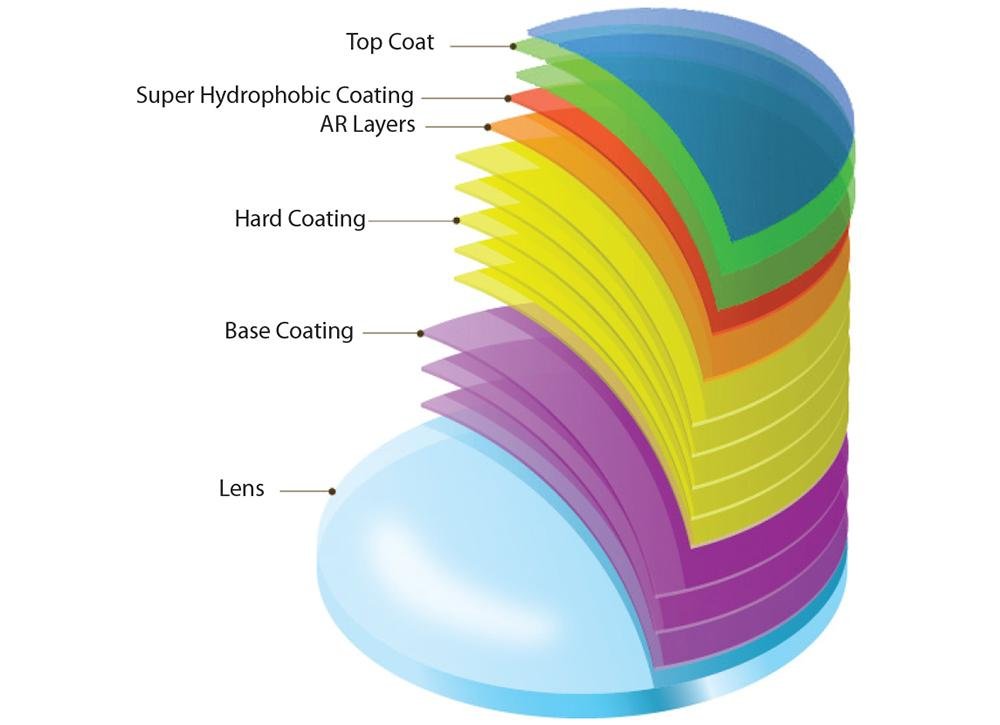

Why should the surface of the lens be hardened?

Compared with glass lens, resin lens has the characteristics of lightness, safety, and comfort, but resin lens friction with dust or gravel in the process of use, resulting in lens wear and forming scratches. These scratches in the center of the lens can interfere with vision.

Therefore, in order to improve the wear resistance of resin lenses, it is necessary to add a layer of anti-wear film to the surface of the lenses. This is the hard coating technology of the lenses, which is called Hard coating.

Evolution of hard coating technology

The first generation of the use of hard coating technology began in the early 1970s, the quartz material is deposited on the surface of a resin lens under vacuum conditions, form a very hard anti-wear film. However, due to the mismatch between the thermal expansion coefficient and the film base material, it is easy to delaminate and crack the film. Instead, it forms the mottle on the surface of the lens, and the effect is not optimal.

The second generation of hard coating technology is the use of the 1980s. The surface of the resin sheet is coated with a material with high hardness and not easy to be brittle and cracked by an immersion process. At this time, anti-reflection coating lenses had appeared and gained the recognition of consumers, but the mismatch between adding hard coating and anti-reflection coating still caused serious lens wear.

The third generation of hard coating technology was developed in the 1990s, mainly in order to solve the problem of wear resistance after coating resin lenses with an anti-reflection film. The hardened material evolved into a polymer organic matrix material.

Fourth-generation coating technology is dominated by silicon atoms, in which the hardened solution contains both organic substrates. It contains inorganic ultrafine particles, including silicon elements, which make the hard coating not only tough but also hard.

Anti-reflection Coating

Anti-reflection Coating, known as reflective coating and antireflection film, is called anti-reflection coating in English, or AR Coating for short. Initially, anti-reflection coating technology was used in the sights of weapons. It was only after the war that the technique was used to improve the performance of eyeglasses. Another problem occurs when taking pictures because the lens's surface is relatively reflective. The resulting photos don't show the eyes of friends who wear glasses. This problem is solved by plating anti-reflection film.

Anti-fouling Coating

The lens coated with anti-reflection film is pretty prone to stain, and the stain will affect the transmittance of the lens. Microscopically, the anti-reflection film shows a porous structure, therefore, the oil is very easy to soak in it. The solution is to coat a layer of anti-fouling film with anti-oil performance on anti-reflection film. The film is very thin and will not change the optical performance of the anti-fouling film. The material is mainly fluoride. There are two processes, one is the immersion method, one is the vacuum coating method (the most commonly used).