Can titanium temples be bended?

Using titanium alloy as the main material, the strength of the spectacle frame becomes larger and the density is smaller. Strong for the frame can be a good guarantee of the structure of the frame, and small density can effectively reduce the weight of the frame, so as to reduce the pressure on the ears and nose of the frame. The toughness of titanium alloy is very good, which can effectively avoid the breaking, bending deformation of the spectacle frame because of an accident.

It is recommended not to bend without authorization. There are many special tools for adjusting glasses. Bending by hand is easy to cause fracture because the force is concentrated at one point. You can take your glasses to a nearby optical shop and have them adjust them. Many big optical shops do this for free.

Frame Selection of Progressive Sunglasses

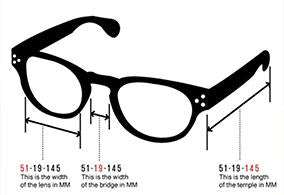

Choose a proper frame range. Only if the frame is not very large and beveled, the frame can be very flat. Because the distance from the glazed to the optical center of a progressive multi-focus lens is 19-17 mm, and the distance between the edges of the frame will be no less than 28 mm if the area inside the lens can be used at close range while maintaining the far sighting field.

Characteristics of titanium frames

Titanium is widely used in the eyewear industry because it is not easy to deform, fade and has strong stability. The glasses frame made of titanium can highlight the noble taste and elegant temperament. The glasses frame made of titanium can be divided into pure titanium, titanium alloy, and beta-titanium frame three kinds. To learn about titanium frames, how to identify pure titanium frames?

Titanium frame has the benefits of low density, high strength, good mechanical properties, and strong corrosion resistance. The frame is very light and not easily corroded by moisture. However, due to the poor process performance of titanium alloy, machining is very difficult, the glasses frame made of hydrogen, oxygen, nitrogen, carbon, and other chemical impurities are more absorbed. The wear resistance of titanium alloy is relatively poor, and the production process is relatively complex, so the cost is relatively high and the workmanship is relatively complicated when using this material to make the spectacle frame. The price is much more expensive than the common spectacle frame.

Leimi Driving Glasses

With professional production and sales of sunglasses/flat glasses/sunglasses, Leimi has been focusing on the fashion aesthetics of sculpted glasses. They are presented through the exquisite selection of materials and fashionable and comfortable design. Leimi carefully makes glasses and discovers the beauty of the world together. Leimi advocates for consumers to experience the number of products through the exquisite materials and fashionable and comfortable design of various glasses products. Leimi believes that it can impress consumers with its products. Since its establishment, Leimi has always been striving to treat customers with high-quality products and good service. At present, Leimi's main products are swimming goggles, reading glasses, sunglasses, lenses, anti-radiation glasses, sunglasses for women, children's glasses, glasses frames, polaroid glasses, driver's glasses.

Use your two hands to wear and take off the glasses.

When you pick and wear glasses, you need to grab the temples with both hands and take them off. When you pick and wear glasses with one hand, it is easy to cause deformation and loosening of the glasses. According to the convention of international glasses design and manufacture, you should fold the left temple first. When placing glasses, keep the convex side of the lens up to avoid scratches on the lenses.

What is hard coating on lenses?

Lenses are mainly added in two kinds of film: anti-reflection film and hard film (and some manufacturers produce anti-fogging film and mirror film, but not common). The anti-reflective film is mainly by coating the front surface of the lens with multiple layers of transparent materials with different refractive index and thickness to reduce the excess reflected light on the surface of the lens, by using the principle of light interference. The film can be applied to both glass and resin lenses. The way of hard film plating is usually a soaking process. After many times of soaking and cleaning, soaking in an organic solution containing ultrafine silicon element for a certain time, and then keeping it at a certain temperature for 4-5 hours, the fixed polymerization process of the film has been completed. The surface wear resistance of CR-39 coating can be increased by 2-4 pH, which is similar to the hardness of optical glass lenses.

What Is an Aspherical Lens?

An aspheric lens is a lens whose surface profiles are not portions of a sphere or cylinder. In photography, a lens assembly that includes an aspheric element is often called an aspherical lens.

The aspheric lens’s more complex surface profile can reduce or eliminate spherical aberration and also reduce other optical aberrations such as astigmatism, compared to a simple lens. A single aspheric lens can often replace a much more complex multi-lens system. The resulting device is smaller and lighter and sometimes cheaper than the multi-lens design.

Aspheric lenses are flatter than traditional lenses, but they still offer the same vision-enhancing benefits. They have a more attractive profile because there is less curvature. In addition, aspherical lenses have a more complex front surface with a gradual curve so that they can perform better by improving the way light refracts onto the retina.

Besides, most aspherical lenses are high-index, which, when combined with the aspheric design, offers a slimmer and lighter option for people who wear glasses so as to improve the look and feel.