How to protect your contact lenses?

When wearing contact lenses, do not drop any eye drops, and only use a special moistening solution for contact lenses. In daily life, we recommend that dry eyes can be relieved with lubricating fluid, but we do not advocate frequent use of lubricating fluid, so as not to make the eyes become dependent on lubricating fluid. The right way is to do blink training. The ingredients contained in the eye drops will remain in the lenses, which will cause certain damage to the eyes and pollute the lenses. Some eye drops can make the lenses tinted after use, which will affect the transmittance and a refractive number of the lenses and make the vision blurred. Ladies who need to make up should wear contact lenses before making up. When removing makeup, remove contact lenses before removing makeup, to avoid the makeup sticking to the lens and damaging the lens and eyes. Lenses should not be lent to others to avoid cross-infection of eye diseases. You can't wear contact lenses while swimming or bathing.

Understand the impact of frame selection on the lens

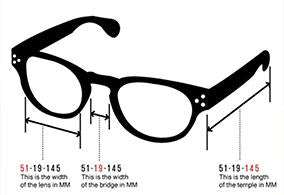

Frame size is an important consideration when using progressive lenses because some progressive lenses work better in frames of different sizes. Since progressive lenses allow you to see at all distances, it's important that the whole range of vision fits within the frame. Therefore, very short lenses and larger lenses are not suitable for progressive lenses.

For collection

Glasses' material and styles are constantly updated. It is more and more light and more beautiful. Early glasses may have become antiques. You might as well collect your retired glasses according to the time and story, and attach the tragic history of the glasses. Perhaps many years later today will become a beautiful memory. You might as well try the nostalgic and literary style.

What are night driving glasses?

Night driving glasses are usually non-prescription glasses with yellow lenses and can be bought in many optical stores or online. Lenses range in color from light yellow to amber, and some night driving glasses have an anti-reflective coating. The yellow night driving glasses have been manufactured and sold for decades. They were originally sold to hunters as shooting glasses because they gave birds a sharper contrast to the sky on overcast or overcast days.

How to buy prescription glasses online

Consumers should choose different styles of frames according to their age and professional characteristics. Because everyone has different face shapes, different interpupillary distances, and different diopters, the size of the frames should vary from person to person.

Lenses are divided into glass lens, resin lens, and PC lens, and you can choose according to your preferences. The glass lens has a stable refractive index, good abrasion resistance, and stable optical performance, but it is relatively heavy and easy to break. Resin lens with high light transmittance is light, safe, and not easy to break, but the surface is easy to wear. PC lens has a high refractive index, but the surface is easy to wear.

Different Types of Progressive Lenses

The first progressive lenses we want to introduce are computer progressive lenses, which are designed for clear vision in office settings. These lenses are ideal when using a computer for over 4 hours a day and help to reduce eye strain.

Computer progressive lenses are intended for indoor use and should not be worn over your regular glasses. The drawback to this is it requires you to have two separate pairs of eyeglasses.

Evolution of hard coating technology

The first generation of the use of hard coating technology began in the early 1970s, the quartz material is deposited on the surface of a resin lens under vacuum conditions, form a very hard anti-wear film. However, due to the mismatch between the thermal expansion coefficient and the film base material, it is easy to delaminate and crack the film. Instead, it forms the mottle on the surface of the lens, and the effect is not optimal.

The second generation of hard coating technology is the use of the 1980s. The surface of the resin sheet is coated with a material with high hardness and not easy to be brittle and cracked by an immersion process. At this time, anti-reflection coating lenses had appeared and gained the recognition of consumers, but the mismatch between adding hard coating and anti-reflection coating still caused serious lens wear.

The third generation of hard coating technology was developed in the 1990s, mainly in order to solve the problem of wear resistance after coating resin lenses with an anti-reflection film. The hardened material evolved into a polymer organic matrix material.

Fourth-generation coating technology is dominated by silicon atoms, in which the hardened solution contains both organic substrates. It contains inorganic ultrafine particles, including silicon elements, which make the hard coating not only tough but also hard.