Many traditional optical stores are complaining about a drop in customer numbers. When we analyze it, we find that the decline in customer numbers is divided into two aspects. The first is the decrease in new customers, which is mainly because the Internet and eye hospitals are fighting for customers from optical stores. The other is the loss of old customers, which is entirely because the optical store did not do the best service, especially the after-sales service.

FACTORY900

It has an avant-garde design and a very three-dimensional look. Many of its designs have gone beyond traditional eyewear. It has been producing plastic frames internally for 80 years. They have a history of pursuing technology, innovation in design, and special technology of plastic molding. And they are said to be available only to them in the world. They created a new type of EYEWEAR with the concept of THE FUTURES EYEWEAR. With the addition of planning and design to internal integrated production, it has been one of the few factory brands to perform almost all processes in the factory. Its unique shape and avant-garde design are highly valued not only in Japan but around the world.

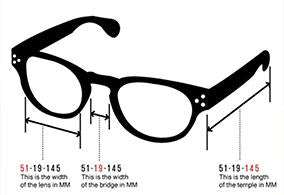

The length of the temple is important.

The glasses should fit snugly over and behind the ears. If they clip behind the ear, mostly, the arm might be too short. The arms of your glasses should be straight back toward your ears, touching only the side of your head, just in front of your ears. If the temple bends too soon, it pushes the glasses under the nose, putting too much pressure on the bridge of the nose and causing a headache.

What is a titanium glasses frame?

Titanium is a metal that has long been used in aerospace, and even in cutting-edge defense because it is so strong and lightweight. Chemically stable, the material is widely used in artificial joints. One thing to emphasize, the titanium welding process is very demanding. The production cost of titanium and titanium alloy glasses is high, and the process has special high requirements in cutting, stamping, welding, and electroplating (for example, welding must be completed in a vacuum), so the price is relatively expensive.

Why does shape memory alloy have memory ability?

It starts with its microstructure. When a metal is solid, its atoms are always arranged in a regular way, forming a lattice. Under different conditions, such as temperature, metal may have a different structure, in which case it is said to be in a different phase. The change from one phase to another is called a phase transition. The properties of a metal change during a phase transition. The temperature at which a metal transforms is called the transition temperature. The difference between a shape memory alloy and other metals is that the phase transformation process in a shape memory alloy is reversible under certain conditions.

The role of the driving glasses

Good driving glasses can be very good to block high energy light, in the evening they can let more faint light enter into our eyes, really solving the problem of only blocking the light and not blocking the road. They have very good night vision function, and can better eliminate glare, better improve the vision of the driver. The driver can drive safely day and night. Strong sunlight improves visual clarity. They are special driving glasses and can brighten polarized light and improve driving safety. With unisex style, high-definition vision, comfort, and light. It can be used on rainy and foggy days and can be used by myopic people. It can effectively filter strong light and high beam lamps, and the long-term use makes you not tired. Both rainy and cloudy days can improve visual clarity. It can effectively prevent strong light, ultraviolet light, and glare is durable and can solve the problem.

Benefits of MR Lenses

It is made of MR series material of Mitsui Chemical, Japan. The biggest advantage is that it is both thin and has good optical properties. Besides, the material has good impact resistance and toughness, so it is not easy to be deformed or broken. Wearing such lenses not only looks more beautiful, but clear and comfortable, and safe at ease. Using a lower density polyurethane material, the lens is lighter and thinner, making it more comfortable to wear. The higher machining success rate increases the processing efficiency and reduces the processing cost. The film compatibility and dyeing properties of MR™ are better than those of ordinary materials, which can improve the quality of functional lenses like photochromic lenses and myopic sunglasses. MR-8™ combines high refractive index, high Abbe number (for better imaging), and better processing performance, suitable for rimless, half-frame, and other glasses, which are less broken and safer. MR-7™ provides better dyeing performance, faster and more uniform color application, and can be used for myopic sunglasses. MR-8 Plus™ is safer and further improves the impact resistance of the lens while maintaining the high Abbe number of MR materials.